Continuous EPS sandwich panel line with ISO quality system and CE certificate | ZHONGYUAN

Review

Description

Product of EPS Sandwich Panel Production Machine

ESP sandwich panel production machine could make the polystyrene core sandwich panel. This sandwich panel product line adopts PLC and touch screen controlling system. It could make both roof and wall sandwich panel with core of polystyrene foam material

| EPS Sandwich Panel Spec | ||

|---|---|---|

| Panel thickness | Mini thickness | 50mm (wall panel) |

| Max. thickness | 200mm(exclude corrugated sandwich panel) | |

| Sandwich Panel Spec | |

|---|---|

| Min. cutting length | 0.4-0.7mm color steel sheet |

| Max. stacking length | 1250mm (can be designed as per client’s requirement) |

| Panel width | 5 tons |

| Panel thickness | 508mm |

| Whole Line Spec | |

|---|---|

| Whole line dimension | about 35000mm × 2500mm × 3000mm |

| Total weight | About 18t |

| Working speed | About 5-7m/min (adjustable) |

| The outpu | 1500m2-2000m2/8hour |

| Control mode | PLC and converter |

| Total power | About 28Kw (as per final designing) |

| Power required | 380V/3phase/50Hz or as per customer's requirement. |

| Air pressure | 0.7Mpa (for buyer to prepare) |

| Suitable working temperature | About 25 degree |

Product application

Due to its high efficiency and simple operation, this forming machine is widely used in the construction of steel structure enclosures, cold storage, and mobile buildings. In order to satisfy various customer requirements, we design and manufacture PU sandwich panel production lines in different specs, models and configurations.

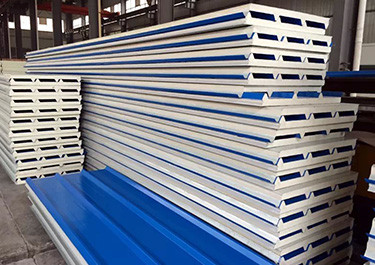

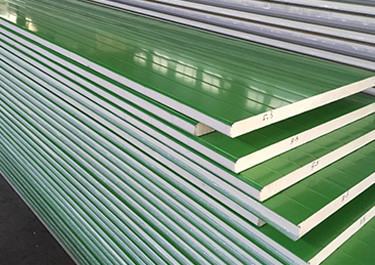

finished product to show

PU sandwich panel from machine Roof panel

Wall panel

If you want to select products through the finished product display, please click here See more product demonstrations

See more product demonstrations

See more product demonstrations

See more product demonstrations