CE and SGS certificate customized stud and truck roll forming machines manuafaturer with ISO quality system | ZHONGYUAN

Review

Description

Stud & track forming machine

| Technical data of Stud & track forming machine | |

|---|---|

| Suitable Material | Cold-rolled steel strip and heat-treated galvanized steel strip |

| Thickness of raw material | 0.5-0.6mm (235-345Mpa) |

| Material of roller | 45# steel being quenched treatment |

| Material of cutter blade& punching die | Cr12 mould steel with quenched treatment, HRC58-60 |

| Material of shaft | High quality 45# steel with heat treatment. Roller grinder milling. |

| Forming speed | about 20m/min |

| Power Requiremen | Main motor power: 5.5 Kw(Depend on final design) |

| Hydraulic station power: 5.5Kw (Depend on final design) | |

| Diameter of shaft for rollers | 55mm |

| Controlling system | Mitsubishi PLC & converter |

| Quantity of rollers | about 15 stations for main rollers |

| Weight of machine | About 6500KGS |

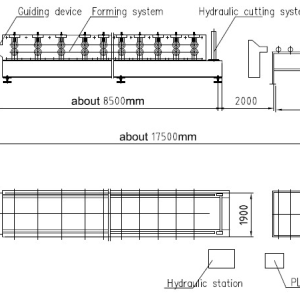

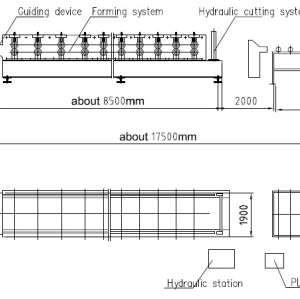

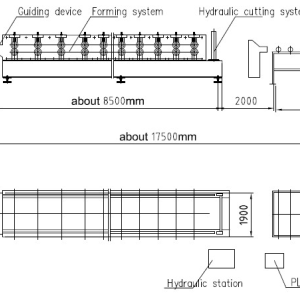

| Size of machine installation | about 15m x 1.7 m x1.4m |

Forming system showing:

Forming system showing:

Product of Stud & track forming machine

Our Roll Forming Machine’s advantages

1. Anti-rust roller: CNC machine tooled, Plated with 0.05mm hard chrome .

2. Heat treatment: Heat treatment for cutting frame to remove the steel stress, to avoid deformation.

3. Cutter blade: Cr12 mould steel with quenched treatment, long life time.

4. High precision: shafts for rollers are tooled by grinding machine at least twice. Rollers are CNC processed to ensure precision performance.

5. People originate: introduced Mitsubishi PLC with touch screen. Friendly man-machine interaction.

6. Excellent services: Technician can be sent to your factory to install the machine and train your workers. Lifetime services for our machines.