Unveiling the Power of Precision: A Deep Dive into Metal Cone Rollers for Versatile Fabrication

- Share

- Issue Time

- Sep 5,2025

Summary

Metal cone rollers are indispensable tools in modern sheet metal fabrication, transforming flat sheets into complex conical shapes. This article delves into the core principles, technological advancements, and diverse applications of these machines. Discover how their precision, customization capabilities, and efficiency are driving innovation across industries, from petrochemical to aerospace, and learn about the key factors in selecting and optimizing these powerful fabricators for unparallele

Unveiling the Power of Precision: A Deep Dive into Metal Cone Rollers for Versatile Fabrication

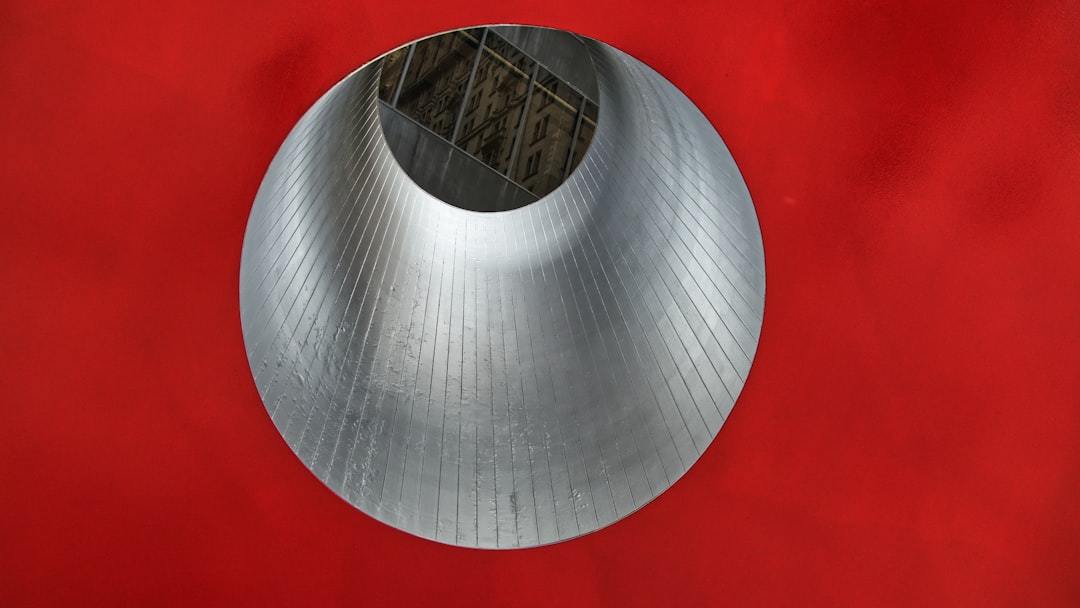

In the intricate world of metal fabrication, the ability to shape flat sheets into robust, geometrically precise structures is paramount. Among the most versatile and critical pieces of equipment enabling this transformation are metal cone rollers. These machines are the unsung heroes behind countless industrial and architectural applications, providing the customizable conical forms essential for everything from sophisticated aerospace components to everyday ventilation systems. This article explores the fundamental aspects, technological prowess, and widespread impact of metal cone rollers, highlighting their role in achieving both customization and versatility in demanding fabrication projects.

What Exactly is a Metal Cone Roller?

A metal cone roller, often referred to as a cone rolling machine or plate roll, is a specialized piece of machinery designed to bend flat metal sheets into conical or truncated conical shapes. Unlike general plate rolling machines that produce cylindrical forms, cone rollers apply force and curvature unevenly across the metal sheet, creating a distinct taper where one end is larger in diameter than the other. This process is crucial for creating parts that require specific angles and transitions for optimal fit and function.

The Foundational Principle: Three-Point Bending

The core working principle behind metal cone rollers is rooted in three-point bending. This method involves applying pressure at three distinct points on the metal workpiece: typically, an upper pressure roller and two lower support rollers (or a combination of active and passive rollers). As the flat, often pre-cut trapezoidal or fan-shaped, metal sheet is fed through these rollers, the pressure applied by the upper roller, combined with the rotational movement, causes localized plastic deformation. The precise adjustment of the roller positions and speeds dictates the taper and radius of curvature, ensuring the final cone matches the desired specifications.

Evolution of Cone Rolling Technology: From Manual to CNC

The evolution of cone rolling technology has been marked by a relentless pursuit of greater accuracy, efficiency, and automation. Early methods relied heavily on manual adjustments and operator skill. Today, advanced metal cone rollers integrate sophisticated control systems, including Computer Numerical Control (CNC) technology. CNC-driven machines allow for programmed precision, automating the complex adjustments required for consistent tapering and reducing the need for extensive manual intervention. This technological leap has significantly enhanced production speeds, accuracy, and repeatability, paving the way for intricate and high-volume fabrication demands.

Key Advantages of Modern Metal Cone Rollers

Modern metal cone rollers offer a myriad of advantages that make them indispensable in contemporary fabrication:

- High Precision and Accuracy: Equipped with advanced control systems, these machines can form cones with extremely tight tolerances and consistent dimensions.

- Versatility in Shape and Size: They accommodate a wide range of cone types, including right-angle, oblique, truncated, and non-truncated cones, and can work with various sheet thicknesses and dimensions.

- Efficiency and Productivity: Automated processes and advanced features minimize setup times and allow for rapid, high-volume production.

- Material Handling: Capable of forming cones from diverse metallic materials, ensuring even stress distribution to prevent cracking or uneven deformation.

- Reduced Manual Effort and Enhanced Safety: Automation reduces operator involvement, leading to safer working environments.

Types of Metal Cone Rollers: 3-Roll vs. 4-Roll Systems

Metal cone rollers primarily come in two configurations: 3-roll and 4-roll bending machines. Each type offers distinct advantages depending on the application and desired level of precision and efficiency.

| Feature | 3-Roll Bending Machine | 4-Roll Bending Machine |

|---|---|---|

| Mechanism | One upper roll, two lower rolls. | One upper roll, one lower roll, two side (pinch) rolls. |

| Material Clamping | Requires external support or additional passes. | Material is continuously clamped, improving safety and precision. |

| Pre-bending | Often requires operator intervention or flipping the workpiece. | Can pre-bend both ends of the plate in a single pass, enhancing efficiency. |

| Accuracy | Good, but generally requires more operator skill. | Higher machining accuracy and efficiency for complex shapes. |

| Ease of Use | More operator dependent. | Easier to operate, especially for conical shapes. |

| Applications | Suitable for common cone rolling, versatile for various tasks. | Ideal for high-precision, rapid production, and heavier plates. |

Precision and Customization: Shaping Diverse Conical Forms

The true power of metal cone rollers lies in their ability to deliver exceptional precision and facilitate extensive customization. From the initial precise cutting of the raw material (often a fan-shaped or trapezoidal blank) to the final forming process, every step is critical. Modern machines can execute intricate tapers and diameters, allowing fabricators to produce concentric reducer cones, eccentric reducer cones, and various other complex geometries required for specific industrial functions.

Beyond basic shaping, customization extends to:

- Material Thickness: Handling everything from thin gauge sheets to thick plates.

- Material Type: Working with steel, aluminum, copper, and various alloys, each with unique properties affecting the rolling process.

- Surface Finishes: Preparing the cone for subsequent finishing processes like welding, painting, or coating.

Versatile Applications Across Core Industries

The versatility of metal cone rollers makes them indispensable across a multitude of industries. Their capability to produce custom conical components means they are integral to sectors requiring high precision and durability. Key applications include:

- Petrochemical Industry: Fabrication of conical heads for storage tanks, pressure vessels, and reactors, where precise tapers are crucial for structural integrity and sealing.

- HVAC and Ductwork: Creation of reduction cones, transitions, funnels, and chimneys for ventilation systems, optimizing airflow and connection points.

- Aerospace and Automotive: Production of specialized components for engine parts, exhaust systems, and aircraft structures, where exacting specifications are paramount.

- Construction: Forming elements for supporting structures, architectural designs, and various infrastructure projects.

- Power Generation and Shipbuilding: Manufacturing of conical steel pipes for transmission towers, boilers, and complex hull structures or masts.

Critical Factors in Choosing and Operating a Cone Roller

Selecting the right metal cone roller and ensuring its optimal operation involves several crucial considerations:

- Material Compatibility: Verify the machine's capacity to handle the specific types and thicknesses of metal you intend to process.

- Precision Requirements: Assess the level of accuracy needed for your applications. Machines with advanced control systems and minimal flat spots at the ends are key for high-precision jobs.

- Productivity and Automation Needs: Evaluate whether a manual, semi-automatic, or fully CNC-controlled machine best suits your production volume and efficiency goals.

- Operator Skill and Training: While modern machines simplify operation, proper training is essential for maximizing output and ensuring safety.

- Safety Features: Look for robust safety mechanisms, especially given the handling of large, heavy metal sheets.

Ensuring Quality: Material Selection and Fabrication Steps

High-quality cone fabrication begins long before the rolling process. It involves a meticulous sequence of steps:

- Material Selection: Choosing the correct metal (e.g., steel, aluminum, stainless steel) based on factors like tensile strength, corrosion resistance, weight, and intended application.

- Dimension Calculation: Accurate calculation of cone dimensions (height, base diameter, top diameter) and developing a precise flat layout.

- Cutting: Precision cutting of the flat sheet into the pre-calculated shape using CNC machining, laser cutters, or plasma cutters.

- Forming: The actual rolling process using the cone roller.

- Welding: Seamlessly welding the edges to ensure structural integrity and a strong, durable seam.

- Calibration and Finishing: Trimming excess material, calibrating for exact dimensions, and applying finishes like sanding, painting, or coating for longevity and appearance.

Maintenance and Longevity for Optimal Performance

To ensure peak performance and extend the lifespan of a metal cone roller, regular maintenance is paramount. This includes routine inspection of rollers for wear, lubrication of moving parts, and calibration checks to maintain accuracy. Hydraulic and electrical systems should be monitored for optimal function, and any signs of unusual operation, such as vibrations or excessive noise, should be investigated promptly. Proper care minimizes downtime, prevents costly repairs, and ensures consistent quality in cone fabrication.

The Future of Metal Cone Rolling: Innovation on the Horizon

The metal fabrication industry is constantly evolving, and cone rolling technology is no exception. The future promises even greater integration of smart manufacturing principles, including:

- Advanced Automation and Robotics: Further reducing manual handling and increasing production speeds through robotic loading, unloading, and inspection.

- IoT Integration: Real-time monitoring of machine performance, predictive maintenance, and operational analytics for optimized workflows.

- Material Innovations: New alloys and composite materials will challenge existing rolling techniques, leading to more adaptive and specialized machines.

- Sustainability: Focus on energy-efficient designs and minimal material waste through optimized processes and 3D modeling.

Embracing Excellence in Cone Fabrication

Metal cone rollers stand as a testament to the sophistication and precision achievable in modern metal fabrication. Their ability to deliver highly customized, durable, and precise conical forms makes them indispensable across a vast spectrum of industries. By understanding their underlying principles, appreciating their technological advancements, and adhering to best practices in operation and maintenance, businesses can leverage these powerful machines to meet the most demanding fabrication challenges, ensuring versatility, efficiency, and superior quality in every finished product.