Rafted Tooling in Metal Roll Forming: How it Works and Its Productivity Benefits

- Share

- Issue Time

- Oct 11,2025

Summary

Rafted tooling represents a pivotal advancement in metal roll forming, designed to significantly enhance productivity, efficiency, and product quality. This modular system replaces traditional, time-consuming tooling changeovers with pre-assembled 'rafts' that contain a series of fully tooled and aligned forming stations. This innovation drastically reduces downtime from hours or even days to typically 30-90 minutes, as setup and calibration occur offline while the machine continues production.

As manufacturers, we're constantly on the lookout for ways to boost efficiency, cut costs, and improve the quality of our products. In the world of metal roll forming, a process central to creating components for everything from solar panels to automotive parts, the tooling we use plays a huge role in achieving these goals. Today, I want to talk about rafted tooling, a game-changing approach in Metal Roll Forming Machine operations that can significantly impact our productivity and profitability.

Traditional roll forming methods often involve time-consuming tooling changeovers that can lead to significant downtime and lost production. However, advancements in metal roll forming machine technology, particularly with rafted tooling systems, offer a solution to these challenges. We'll dive into how this modular and flexible tooling setup works and explore the many benefits it brings to our operations, helping us stay competitive in a dynamic industry.

Key Takeaways

For manufacturers operating in high-demand sectors, efficiency is not just a goal; it's a necessity for survival and growth. Rafted tooling technology in metal roll forming machines presents a transformative solution designed to meet these challenges head-on. Here are the crucial takeaways from integrating this advanced system into your production line:

- Drastic Reduction in Downtime: The most significant advantage of rafted tooling is the dramatic cut in changeover times. Traditional tooling changes can take a full shift or even multiple days, bringing production to a complete halt. With rafted systems, the entire toolset for a new profile is pre-mounted on a "raft" or sub-plate. This allows the changeover to be completed in a fraction of the time, often in less than an hour. This massive reduction in downtime directly translates to increased production capacity and the ability to meet tighter deadlines.

- Enhanced Operational Flexibility: Markets are more dynamic than ever, demanding a wider variety of product profiles, often in smaller batch sizes. Rafted tooling directly addresses this need. By enabling rapid changeovers, it makes short production runs economically viable. Manufacturers can switch between producing different components—such as various steel frame sections or roofing panel profiles—multiple times a day without suffering significant productivity losses. This agility allows businesses to cater to a broader customer base and adapt quickly to shifting market trends.

- Superior and Consistent Product Quality: In a rafted system, tooling is set, aligned, and calibrated on the raft offline, in a controlled environment. Once this raft is loaded into the metal roll forming machine, the settings are already perfected. This eliminates the lengthy on-machine adjustments and trial-and-error runs common with traditional tooling. The result is exceptional consistency from the very first part to the last, significantly reducing material scrap and ensuring that every product meets exact specifications.

- Significant Long-Term Cost Savings: While the initial investment in a rafted tooling system and multiple rafts may be higher than for traditional setups, the return on investment is compelling. Cost savings are realized through multiple avenues: reduced labor costs due to shorter and simpler changeovers, minimized material waste from fewer setup errors, and increased revenue from higher machine uptime and output. Furthermore, maintenance can be performed on one raft offline while another is in operation, preventing production delays and maximizing the machine's overall lifecycle value.

- Improved Safety and Maintenance Workflow: Handling individual, heavy tooling stands during a traditional changeover poses ergonomic and safety risks to operators. Rafted systems streamline this process. The entire raft is typically moved with an overhead crane, minimizing manual handling of heavy components. This not only creates a safer work environment but also simplifies maintenance. Technicians can work on a raft at a workbench with better access and lighting, rather than in the tight confines of the forming machine, leading to more thorough and efficient repairs.

Understanding the Fundamentals of Metal Roll Forming Machine Operations and Tooling

To fully appreciate the innovation of rafted tooling, it's essential to first grasp the core principles of the metal roll forming process and the role traditional tooling plays within it. This foundational knowledge highlights the challenges that rafted systems were designed to overcome.

How a Metal Roll Forming Machine Works

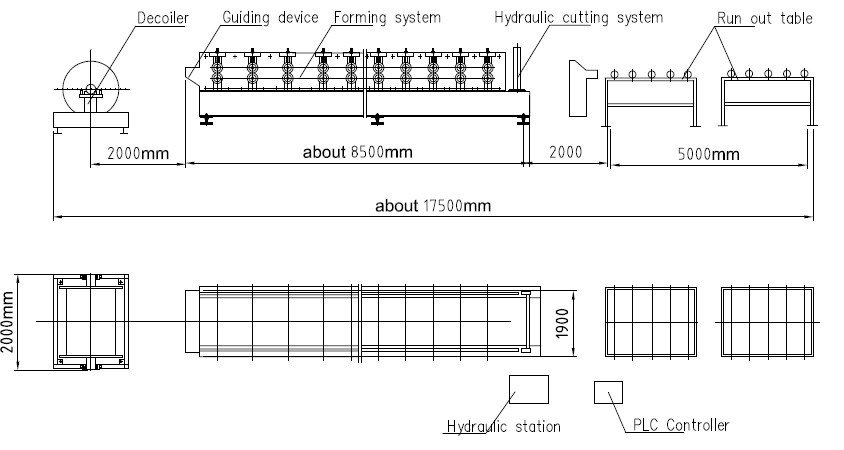

A metal roll forming machine operates on a principle of continuous, gradual shaping. The process begins with a large coil of flat sheet metal, which is loaded onto a decoiler. This decoiler carefully unwinds the metal strip and feeds it into the machine, often through a straightener to remove any existing imperfections from the coil.

Once inside the machine, the metal strip travels through a series of stations, each equipped with a set of precisely designed rollers. These rollers are arranged in pairs, one above and one below the metal strip. Each successive station makes a small, incremental bend to the material. As the strip progresses through the line, these slight modifications accumulate, gradually forming the metal into its final, complex cross-sectional profile without the need for heat. The number of stations required depends on the complexity of the final shape. After passing through the last forming station, the newly shaped profile moves into a cut-off press, which shears it to the specified length. The finished parts are then moved to a run-out table for stacking and handling.

The Importance of Traditional Tooling in Metal Roll Forming

In a traditional metal roll forming setup, the "tooling" refers to the entire collection of rollers, dies, and spacers that are mounted directly onto the machine's drive shafts. These components are the heart of the process, as their specific design and arrangement dictate the final shape of the product. The tooling is typically crafted from hardened and highly durable D2 tool steel, designed to withstand immense pressure and wear over millions of feet of production.

The importance of this tooling cannot be overstated. It is responsible for ensuring part consistency, dimensional accuracy, and overall quality. Engineers design each set of rollers to progressively alter the metal's shape, and this progression is critical. If the bends are too aggressive, the material can crack or become stressed; if they are too gradual, it increases the required number of stations and cost.

However, the major drawback of traditional tooling lies in its fixed nature. When a manufacturer needs to produce a different profile, the entire machine must be shut down. Operators then undertake a laborious process of manually removing each heavy roller and spacer set from every station and installing the new tooling. This changeover can take anywhere from four to 12 hours, or even longer, depending on the machine's complexity. During this extensive downtime, the machine is not producing parts, leading to significant losses in productivity and efficiency.

Introducing Rafted Tooling: A Modular Approach to Metal Roll Forming Machine Efficiency

In response to the productivity bottlenecks caused by traditional setups, the industry developed a more advanced and flexible solution: rafted tooling. This modular innovation fundamentally changes the way changeovers are performed, transforming a time-consuming task into a streamlined, efficient process.

What is Rafted Tooling in a Metal Roll Forming Machine?

Rafted tooling represents a fundamental shift from traditional, fixed tooling. In a rafted system, the forming rollers and their stands are not mounted directly to the bed of the metal roll former. Instead, groups of forming stations are pre-assembled onto large, removable sub-plates known as "rafts".

Each raft holds a series of fully tooled and aligned forming passes. A complete roll forming line might consist of several of these rafts placed end-to-end. The key innovation is that these entire rafted sections can be lifted out of the machine and replaced with a different set of rafts pre-tooled for another product profile. This modular design means that instead of changing hundreds of individual components on the machine, operators only need to swap out a few large, self-contained units.

The Mechanics of Rafted Tooling Systems

The primary advantage of a rafted system is the ability to perform tooling setup offline. While the machine is busy running one product, technicians can be in a separate, dedicated area preparing the next job. They mount, align, and precisely calibrate the rollers for the new profile on a spare set of rafts.

The changeover process itself is dramatically simplified:

- Offline Preparation: The complete tooling for the next production run is assembled and fine-tuned on a spare set of rafts. This is done while the current job is still running, eliminating setup tasks from the machine's downtime.

- Stop and Swap: Once the current production run is finished, the machine is stopped. An overhead crane or a large forklift is used to lift the "old" rafts out of the machine bed.

- Install New Rafts: The pre-set "new" rafts are then lowered into the same position. They are designed with precision locating pins and automated drive couplings that ensure they lock into place correctly and connect to the machine's power source.

- Resume Production: With the new rafts secured, the machine is ready to start the next production run. The entire on-machine process, which traditionally took many hours, can be reduced to as little as 30-45 minutes.

This "plug-and-play" approach transforms the entire workflow, moving the time-consuming setup tasks away from the main production line.

Unlocking Enhanced Productivity with Rafted Tooling Metal Roll Forming Machines

The adoption of rafted tooling is not just an incremental improvement; it is a strategic leap forward in manufacturing productivity. By redesigning the changeover process, this technology directly addresses the most significant sources of lost time and revenue in roll forming operations, leading to substantial gains in output and cost-efficiency.

Minimizing Downtime and Boosting Output of the Metal Roll Forming Machine

The single greatest benefit of a rafted tooling system is the radical reduction in machine downtime. Traditional changeovers can sideline a machine for an entire 8-hour shift or more. With rafted tooling, this unproductive period can be slashed by 50-80%, with many changeovers completed in under an hour. This is because the laborious process of setting up and calibrating tooling is performed offline, while the machine is still generating revenue.

This saved time translates directly into increased production capacity. Consider a facility that performs three tooling changes per week.

| Metric | Traditional Tooling | Rafted Tooling | Productivity Gain |

|---|---|---|---|

| Changeover Time | ~8 hours | ~1 hour | 7 hours saved per changeover |

| Weekly Downtime | 24 hours (3 x 8) | 3 hours (3 x 1) | 21 hours of production gained |

| Annual Uptime Gain | - | 1,092 hours (21 x 52) | Over 1,000 extra hours of production |

As the table illustrates, the cumulative effect over a year is staggering. By converting thousands of hours of downtime into productive uptime, a rafted roll former can significantly boost total output without needing to run faster or longer. This allows manufacturers to take on more jobs, shorten lead times, and ultimately increase revenue and profitability.

Cost-Effectiveness and Material Waste Reduction in Metal Roll Forming Machine Operations

While the initial investment in a rafted system may be higher than a traditional line, the long-term cost savings are substantial and multifaceted.

- Reduced Labor Costs: Traditional tooling changeovers are labor-intensive, often requiring multiple operators for a full shift. A rafted changeover is a much faster process that can be handled by fewer personnel. With thousands of labor hours saved annually, the reduction in direct and overtime labor costs is significant.

- Minimized Setup Scrap: A major source of material waste in roll forming is the setup and "dial-in" process after a tooling change. Operators may need to run and discard a considerable amount of material while making fine adjustments to achieve the correct profile specifications. Rafted tooling virtually eliminates this problem. Since the rafts are pre-set and calibrated offline, they produce dimensionally accurate parts from the very beginning of the run. This drastic reduction in setup scrap not only saves money on raw materials but also contributes to more sustainable manufacturing practices.

- Lower Per-Unit Cost: By increasing machine uptime and reducing labor and material waste, rafted tooling directly lowers the production cost of each part. This allows for more competitive pricing and higher profit margins, strengthening the company's position in the market.

Ultimately, the cost-effectiveness of rafted tooling is realized through a holistic improvement in operational efficiency. The initial capital outlay is offset by ongoing savings in labor, material, and the increased revenue generated from higher productivity.

Achieving Superior Quality and Adaptability with Rafted Tooling Metal Roll Forming Machines

Beyond the immediate gains in productivity and cost savings, rafted tooling introduces a higher level of precision and flexibility to the manufacturing floor. These advantages allow companies to not only produce better parts but also to respond more effectively to the dynamic demands of the modern market.

Enhanced Quality Control and Production Consistency in Metal Roll Forming Machine Products

A key advantage of rafted tooling is the dramatic improvement in part quality and consistency. With traditional tooling, every changeover introduces the risk of human error. The on-machine adjustments required to align each roller can lead to slight variations, affecting part tolerances.

Rafted tooling mitigates this risk by moving the critical alignment process offline. In a controlled environment, away from the pressures of the production floor, technicians can use precision instruments to set up and validate the tooling on the raft. This ensures that every roller is perfectly aligned before the raft is ever loaded into the machine.

The benefits of this offline setup include:

- Guaranteed Repeatability: Once a raft is set and validated for a specific profile, it can be stored. When it's loaded back into the machine for a future run, it will produce the exact same part specifications as before, eliminating variations between batches.

- Tighter Tolerances: With the setup process removed from the production line, more time can be dedicated to achieving a perfect calibration. This allows for the consistent production of parts that meet even the most stringent quality standards.

- First-Part-Good Capability: Because the tooling is already dialed in, the first part that comes off the line after a changeover is almost always a usable, in-spec product. This eliminates the "warm-up" period of trial and error, saving valuable material and time.

This heightened level of quality control is crucial for industries like automotive, aerospace, and construction, where precision and consistency are non-negotiable.

Flexibility to Meet Evolving Market Demands with Your Metal Roll Forming Machine

The modern manufacturing landscape is characterized by increasing product variety and demand for smaller, more customized orders. Traditional roll forming, with its long and costly changeovers, is ill-suited for this environment. It excels at high-volume production of a single product but struggles to be profitable with short runs.

Rafted tooling completely changes this dynamic. The ability to switch between profiles quickly and cost-effectively provides manufacturers with unprecedented operational flexibility.

- Enabling Short Production Runs: With changeover times reduced from hours to minutes, it becomes economically viable to produce smaller batches of different profiles. A machine can be switched to produce a short run of a custom part and then quickly switched back to a high-volume job with minimal loss of productivity.

- Supporting Just-in-Time (JIT) Manufacturing: Rafted tooling is a key enabler of JIT principles. Manufacturers can produce what is needed, when it is needed, without building up large, costly inventories of finished goods. This responsiveness reduces storage costs and waste associated with overproduction.

- Rapid Adaptation to Market Changes: When new product designs are required, a new set of rafts can be tooled and tested offline without interrupting current production. This allows companies to introduce new products and adapt to market trends with minimal lead time, providing a significant competitive advantage.

By making roll forming a more agile and responsive process, rafted tooling empowers manufacturers to move away from a purely high-volume model and embrace a more flexible, customer-centric approach.

Practical Considerations for Implementing Rafted Tooling in Your Metal Roll Forming Machine Line

While the benefits of rafted tooling are clear, a successful implementation requires careful consideration of operational factors like maintenance and investment strategy. Understanding these practical aspects ensures that a company can maximize the long-term value and performance of their rafted system.

Maintenance and Repair Advantages of Rafted Tooling for Your Metal Roll Forming Machine

A rafted tooling system streamlines maintenance and repair, directly contributing to higher overall machine availability. The modular design fundamentally changes how maintenance is scheduled and performed, minimizing its impact on production.

- Offline Maintenance: The most significant advantage is the ability to perform maintenance on a set of rafts offline. If a roller bearing fails or a tool requires adjustment, the entire affected raft can be swapped out with a spare. Production continues with the backup raft while the original is moved to a maintenance area for repair. This eliminates the need to shut down the entire production line for what could be a lengthy repair on a traditional system.

- Improved Accessibility and Safety: Working on tooling in a dedicated, well-lit maintenance bay is far safer and more efficient than performing repairs inside the cramped confines of the machine. Technicians have better access to all components, can use proper workbenches and lifting equipment, and are not rushed by production pressures. This leads to higher-quality, more thorough repairs.

- Proactive Maintenance scheduling: With multiple sets of rafts, maintenance can be scheduled proactively rather than reactively. A raft can be pulled for routine inspection and preventative maintenance (e.g., bearing replacement, re-shimming, tool polishing) while another identical raft takes its place on the line. This approach prevents unexpected breakdowns and extends the life of the tooling.

- Maximized Machine Uptime: By decoupling maintenance from production time, the roll forming machine itself remains in operation for a much higher percentage of its available hours. The workflow becomes a continuous cycle of running production, swapping rafts, and performing maintenance in parallel, a model that significantly boosts overall equipment effectiveness (OEE).

Comparing Leasing vs. Purchasing a Portable Metal Roll Forming Machine with Rafted Tooling

When investing in a portable metal roll forming machine equipped with rafted tooling, businesses face a critical decision: should they purchase the equipment outright or lease it? Both options have distinct financial and operational implications, and the right choice depends on the specific needs and capital strategy of the company.

| Feature | Purchasing | Leasing |

|---|---|---|

| Initial Cost | High upfront capital expenditure. Requires a significant initial investment for the machine and multiple sets of rafts. | Low upfront cost. Spreads the expense into predictable monthly payments. |

| Long-Term Cost | Often cheaper in the long run as there are no ongoing interest or lease fees after the initial purchase. | Typically more expensive over the life of the lease due to interest and associated fees. |

| Ownership & Equity | The machine is a company asset. Builds equity and can be resold to recoup part of the investment. | The leasing company retains ownership. No equity is built, and the machine is returned at the end of the term. |

| Maintenance | The owner is fully responsible for all maintenance, repairs, and associated costs. | Maintenance terms vary. Some leases may include maintenance coverage, while others make the lessee responsible. |

| Technology Upgrades | Upgrading to newer technology requires selling the old machine and purchasing a new one, which can be a slow process. | Easier to upgrade to the latest equipment at the end of the lease term, ensuring access to modern technology. |

| Tax Implications | The purchase may qualify for tax deductions under Section 179, allowing a significant write-off in the year of purchase. | Lease payments are typically treated as a fully tax-deductible operational expense. |

| Customization | Owner has complete freedom to customize or modify the machine and tooling as needed. | Customization is often restricted or forbidden by the terms of the lease agreement. |

Key Considerations:

- For Businesses with Steady Cash Flow and High Volume: Purchasing is often the more financially sound decision in the long run. It provides an asset for the company and eliminates ongoing payments. The ability to resell the equipment adds to its long-term value.

- For Startups or Businesses with Variable Workloads: Leasing offers a lower barrier to entry, preserving capital for other operational needs. It provides flexibility, allowing a company to use state-of-the-art equipment without a massive upfront commitment and making it easier to adapt if business needs change.

Ultimately, the decision to lease or buy a rafted roll forming system is a strategic one. It requires a careful analysis of the company's financial position, production forecasts, and long-term goals.

FAQs (Frequently Asked Questions)

To provide further clarity, here are answers to some of the most common questions about rafted tooling in metal roll forming.

1. Is rafted tooling suitable for all types of roll forming operations?

While highly beneficial, rafted tooling is most impactful for operations that require frequent profile changes. Manufacturers who produce a wide variety of products or cater to customers with a need for smaller, custom batches will see the most significant return on investment. For a company that produces a single, high-volume profile with very few changeovers, the additional upfront cost of a rafted system may not be as easily justified compared to a dedicated, traditional line.

2. What is the typical changeover time for a rafted system compared to a traditional one?

A traditional tooling changeover can take anywhere from 4 to 12 hours, and in some complex cases, even multiple days. In stark contrast, a rafted tooling changeover can typically be completed in 30 to 90 minutes. Some studies and real-world applications show changeover time reductions of 50% to 80%, transforming hours or days of downtime into just a fraction of that time.

3. What is the initial investment cost for a rafted system compared to a traditional roll forming machine?

The initial investment for a rafted system is higher. This is because, in addition to the roll forming machine itself, the company must purchase multiple raft sub-plates—at least one for each profile to be run, plus a spare set for offline setup. While the roll forming machine's base might be comparable in cost, the additional expense comes from these interchangeable raft modules and the duplicate sets of tooling required. However, this higher upfront cost is designed to be offset by long-term savings in labor, reduced scrap, and massively increased uptime.

4. Can an existing, traditional roll forming machine be retrofitted with rafted tooling?

In some cases, yes. Retrofitting an older, traditional machine with a rafted system is possible, but it depends heavily on the original machine's design and construction. The process can be complex and costly. It involves significant modifications to the machine bed to accommodate the locking mechanisms and drive connections for the rafts. It's often more cost-effective to invest in a new machine that is purpose-built for rafted tooling from the outset. A consultation with an experienced machine manufacturer is essential to determine feasibility.

5. How does rafted tooling affect the skill requirements for operators?

Rafted tooling can simplify the on-machine tasks for operators while shifting the high-skill work to an offline environment. The on-machine changeover becomes a more straightforward mechanical process of swapping large modules, which reduces the risk of on-the-fly adjustment errors. However, the need for skilled technicians does not disappear; it is transferred to the offline setup area. Here, technicians with expertise in precise tool alignment and calibration are crucial for preparing the rafts. This separation of tasks can lead to a more specialized and efficient workforce.

Conclusion

From what we've seen, rafted tooling offers a significant competitive advantage in the metal roll forming industry. Its ability to dramatically reduce changeover times, enhance quality, and provide greater adaptability makes it a valuable investment for any operation looking to maximize production and profitability. By minimizing downtime, reducing material waste, and ensuring consistent, high-quality output, this modular approach addresses the core challenges of traditional roll forming head-on.

By embracing rafted tooling for our metal roll forming machines, we can not only streamline our processes and reduce costs but also improve our ability to meet diverse customer needs and uphold the highest quality standards. It's a clear path to staying ahead in today's fast-paced manufacturing landscape. As market demands continue to shift toward greater customization and just-in-time delivery, the flexibility and efficiency offered by rafted systems will become an increasingly vital component of a successful metal forming operation. We encourage you to share your thoughts on this technology and discuss how it might impact your own production strategies.