Mastering Modern Roofing: A Deep Dive into Standing Seam Roll Forming Machines and Their Edge Over Alternatives

- Share

- Issue Time

- Oct 21,2025

Summary

Explore the world of standing seam roll forming machines, the gold standard in metal roofing. This guide covers how they work, their key advantages, and a detailed comparison against corrugated and tile roll formers, helping you understand why they are the preferred choice for durable, weather-tight, and aesthetic roofing projects.

Why Standing Seam is Dominating the Metal Roofing Market

In the construction industry, the demand for durable, energy-efficient, and aesthetically pleasing roofing solutions is constantly growing. Standing seam metal roofs have emerged as a top contender, celebrated for their clean lines, superior durability, and exceptional weather resistance. This profile's rise in popularity is directly linked to the advanced technology that produces it: the standing seam roll forming machine. These machines are the engines behind the shift towards higher-quality metal roofing, offering precision and efficiency that traditional methods cannot match. For contractors and manufacturers, understanding this equipment is key to staying competitive and delivering top-tier results.

What Exactly is a Standing Seam Roll Forming Machine?

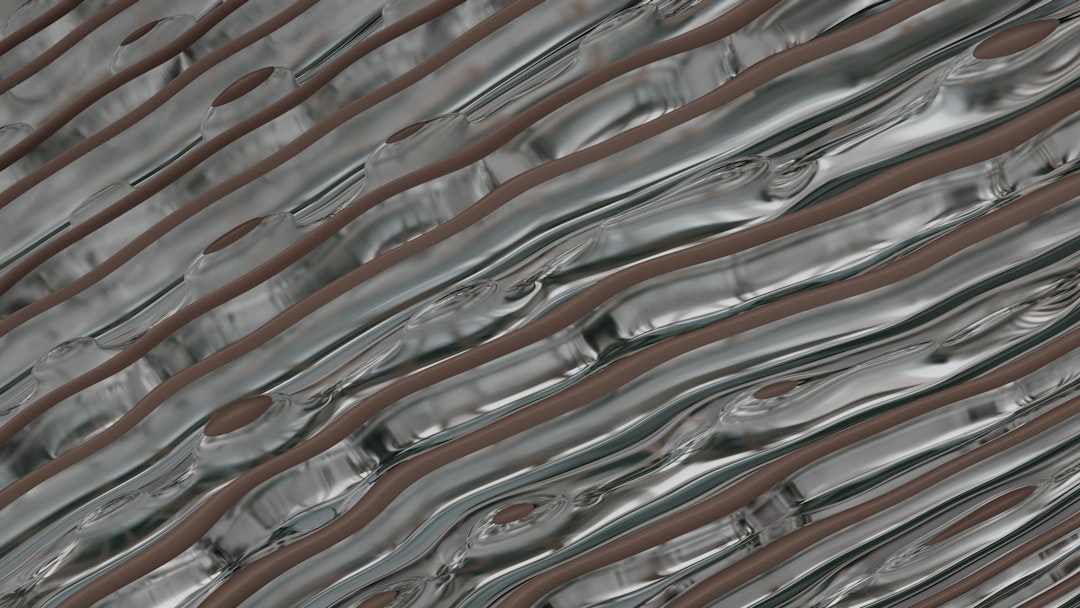

A standing seam roll forming machine is a specialized piece of equipment designed to continuously shape flat metal coil into precise roofing panels with raised, interlocking seams. Unlike other roofing systems that rely on exposed fasteners, standing seam panels connect via these vertical seams, which are mechanically locked together. This creates a continuous, watertight barrier from the eave to the ridge. The machines themselves range from large, stationary in-plant systems to versatile portable roll formers that can produce panels directly at the job site.

The Inner Workings: From Coil to Panel

The roll forming process is a marvel of incremental engineering. It begins by loading a large metal coil (typically steel, aluminum, or copper) onto a decoiler. The flat metal strip is then fed into the machine, where it passes through a series of precision-calibrated rollers. Each set of rollers, or forming station, slightly bends the metal, gradually shaping it into the final panel profile. This progressive process ensures the metal's integrity is maintained without stress or thinning. Once the panel reaches the desired length, a shear cuts it cleanly. Modern machines are often equipped with PLC (Programmable Logic Controller) systems, allowing operators to input exact lengths and quantities, automating the process for maximum efficiency and minimal waste.

Unmatched Advantages of Standing Seam Systems

The popularity of standing seam roofing isn't just about looks. The system, produced by specialized roll formers, offers tangible benefits that set it apart:

- Superior Weather-Tightness: The interlocking seams sit above the panel's flat surface, minimizing the risk of water infiltration. With no exposed screws, one of the most common points of failure in other metal roofs is eliminated.

- Thermal Movement: Metal expands and contracts with temperature changes. Standing seam systems use a concealed clip system that allows the panels to move freely, preventing stress, buckling, and damage to the fasteners.

- Longevity and Durability: By eliminating exposed fasteners and reducing water penetration risk, standing seam roofs have an exceptionally long lifespan. The use of high-quality materials like galvanized steel further enhances their resistance to corrosion.

- Aesthetic Versatility: These machines can be adjusted to produce panels of various widths and seam heights, offering architects and builders significant design flexibility.

Standing Seam Machine vs. Corrugated Roll Former

Corrugated roofing is one of the most traditional forms of metal roofing, known for its wavy pattern and affordability. However, the machines and the final products differ significantly from standing seam systems.

- Fastening Method: Corrugated panels are installed with exposed fasteners that pierce the metal, creating potential entry points for water over time. Standing seam machines create panels that use hidden clips and seams.

- Weather Resistance: While effective, the exposed fasteners of corrugated roofing make it more vulnerable to leaks as seals degrade. Standing seam is inherently more water-resistant due to its raised, sealed-seam design.

- Application: Corrugated is often used for agricultural and basic industrial buildings where cost is the primary driver. Standing seam is preferred for commercial, architectural, and high-end residential projects where long-term performance and aesthetics are paramount.

Standing Seam Machine vs. Metal Tile Roll Former

Metal tile roll formers create panels that mimic the look of traditional ceramic or concrete tiles, combining classic aesthetics with the lightness of metal. The comparison here is more about style and function.

- Process Complexity: Glazed tile roll formers often include a stamping or pressing stage to create the tile shape, which can make the machine more complex and slower than a continuous standing seam former.

- Water Shedding: Both are excellent at shedding water, but standing seam's long, continuous panels from ridge to eave offer fewer horizontal laps, reducing the number of potential entry points for wind-driven rain compared to shorter tile panels.

- Aesthetics: The choice is largely stylistic. Tile profiles offer a traditional, textured look, whereas standing seam provides a clean, modern, linear appearance.

Standing Seam Machine vs. Press Brakes and Folders

Before roll formers became widespread, metal roofing panels were often fabricated using press brakes or folders. This manual method is still used for custom flashing and small jobs but is inefficient for producing long panels.

- Speed and Efficiency: A roll forming machine can produce hundreds of feet of panels per minute without stopping. A press brake is a slow, manual process, bending one section at a time.

- Consistency: Roll formers deliver perfectly uniform panels every time. Manual fabrication is subject to operator skill and human error, leading to inconsistencies.

- Length Limitations: Press brakes are limited to the length of the machine (typically 10-12 feet), requiring horizontal seams on long roof runs. Portable standing seam roll formers can produce continuous panels over 100 feet long.

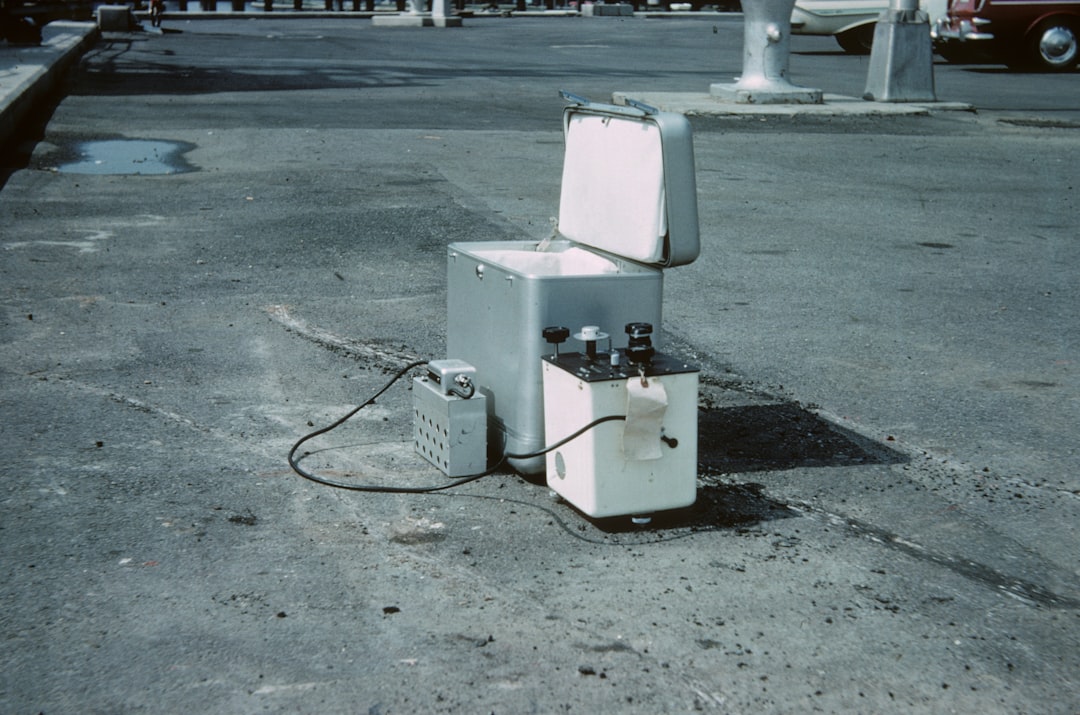

The Rise of Portable Roll Forming

A game-changer in the industry is the portable standing seam machine. These trailer-mounted units can be taken directly to a construction site. This offers several huge advantages:

- Reduced Waste: Panels are formed to the exact length needed, eliminating the need to order longer panels and cut them down.

- No Shipping Damage: Producing panels on-site means they don't risk being scratched or dented during transport.

- Continuous Lengths: On-site forming allows for the creation of extremely long panels without seams, which are impossible to transport from a factory. Some contractors even crane the machine onto the roof to run panels directly into place.

Comparison Table: Metal Roof Equipment

| Feature | Standing Seam Roll Former | Corrugated Roll Former | Metal Tile Roll Former | Press Brake / Folder |

|---|---|---|---|---|

| Seam Type | Interlocking, Raised Seam | Overlapping, Wavy | Overlapping, Stamped Tile Shape | Custom Bends |

| Fasteners | Concealed (Clips) | Exposed (Screws) | Exposed or Concealed | N/A (Fabrication Tool) |

| Weather Tightness | Excellent | Good | Very Good | Depends on Seam Type |

| Production Speed | High (Continuous) | High (Continuous) | Medium (Includes Stamping) | Very Low (Manual) |

| Best Use Case | Architectural, Commercial | Agricultural, Industrial | Residential, Aesthetic | Custom Flashing, Prototypes |

| On-Site Capability | Excellent (Portable Models) | Possible | Less Common | Not Practical for Panels |

Choosing the Right Machine for Your Business

Investing in a roll forming machine is a significant decision. For businesses aiming to specialize in high-quality, durable roofing, a standing seam machine is the clear choice. Key considerations include:

- Portability: Will you benefit from on-site production?

- Profile Versatility: Do you need a machine that can produce multiple panel profiles and widths?

- Production Speed: What is your required output?

- Material Compatibility: What gauges and types of metal will you be using?

Conclusion: Investing in the Future of Roofing

The standing seam roll forming machine represents the pinnacle of metal roofing technology. It provides unmatched efficiency, precision, and quality, producing panels that deliver superior protection and aesthetics. While alternatives like corrugated and tile machines have their place, the standing seam system's combination of weather-tightness, durability, and design flexibility makes it the industry standard for modern construction. For contractors looking to elevate their business, mastering the use of a standing seam machine is not just an option—it's an investment in the future.