Drip Edge and Downspout Roll Forming Machines

- Share

- Issue Time

- Jul 5,2024

Summary

Explore our drip edge and downspout roll forming machines for creating precise and durable components.

Introduction: Importance of Drip Edges and Downspouts

Drip edges and downspouts play a crucial role in protecting buildings from water damage. By directing rainwater away from the structure, they help prevent erosion, moisture infiltration, and structural damage. Investing in high-quality drip edge roll forming machines and gutter downspout machines ensures that you produce precise and durable components for effective water management.

Product Listings: Machine Specifications

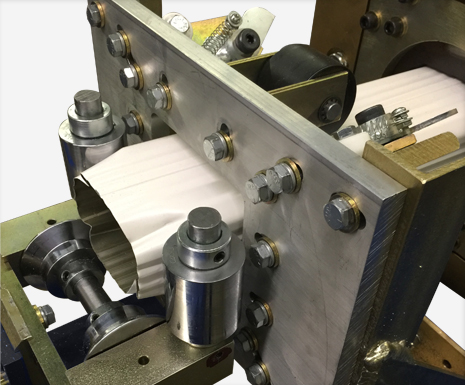

Drip Edge Roll Forming Machine

Drip Edge Roll Forming Machine

- Material thickness: 0.3-0.8mm

- Forming stations: 12-18

- Motor power: 5.5KW

- Control system: PLC

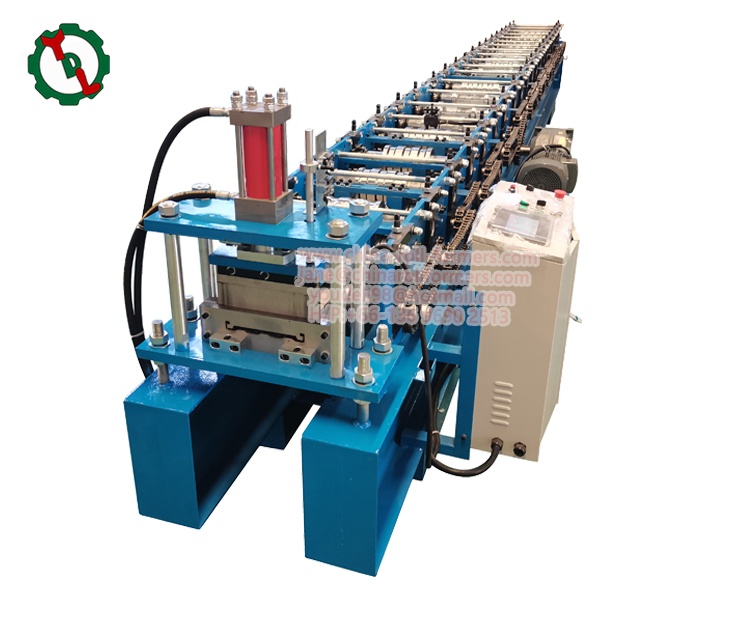

Gutter Downspout Machine

Gutter Downspout Machine

- Material thickness: 0.4-1.0mm

- Forming stations: 16-24

- Motor power: 7.5KW

- Control system: PLC

Down Pipe Roll Forming Machine

Down Pipe Roll Forming Machine

- Material thickness: 0.4-1.2mm

- Forming stations: 16-22

- Motor power: 7.5KW

- Control system: PLC

Square Downpipe Roll Forming Machine

Square Downpipe Roll Forming Machine

- Material thickness: 0.5-1.2mm

- Forming stations: 18-26

- Motor power: 11KW

- Control system: PLC

Fascia Roll Forming Machine

Fascia Roll Forming Machine

- Material thickness: 0.4-1.0mm

- Forming stations: 14-20

- Motor power: 5.5KW

- Control system: PLC

Benefits: Precision, Durability

Our drip edge roll forming machines and gutter downspout machines are designed to deliver exceptional precision and durability. The advanced down pipe roll forming machines ensure that each component meets exact specifications, reducing waste and improving efficiency. The robust construction of our square downpipe roll forming machines guarantees long-lasting performance, even under harsh conditions. Additionally, our fascia roll forming machines offer versatile solutions for producing high-quality fascia components.

Applications: Use Cases in Construction

Drip edge roll forming machines and gutter downspout machines are essential tools in the construction industry. They are widely used in residential, commercial, and industrial projects to create components that protect buildings from water damage. Down pipe roll forming machines are particularly valuable for producing downpipes that efficiently channel rainwater away from structures. Square downpipe roll forming machines offer a sleek, modern aesthetic for contemporary buildings, while fascia roll forming machines provide reliable solutions for creating fascia boards that enhance the overall appearance and functionality of roofing systems.

FAQs: Common Questions About Drip Edge and Downspout Machines

What materials can be used with these machines?

Our drip edge roll forming machines and gutter downspout machines are compatible with a variety of materials, including galvanized steel, aluminum, and copper.

How do I maintain the machines?

Regular maintenance includes cleaning, lubrication, and inspection of moving parts. Detailed maintenance instructions are provided with each down pipe roll forming machine and square downpipe roll forming machine.

Can these machines be customized?

Yes, we offer customization options for all our fascia roll forming machines to meet specific project requirements.

What is the lead time for delivery?

The lead time varies depending on the machine specifications and customization requirements. Please contact us for detailed information on the delivery schedule for your drip edge roll forming machine or gutter downspout machine.